The use of discontinuous or overtwisted yarns has always created the problem of the fabric screwing, that is to say the commonly called "turn" Such disadvantage depends on several grounds: some of which have an impact within certain limits, others determinately.

Limited incidence factors: knitting-feeds number, direction of rotation.

Determinative incidence factors: yarn twist and consequent "fabric screwing.

Up to now, to limit or reduce the problem, have been used the following methods:

1) the use of balanced twisted yarn

2) the use of opposite twisted yarns (s/z)

3) the "helical" fabric cut

The first two methods, by using yarns produced correctly, can guarantee the lack of screwing, but the former is very expensive and the latter isn't appreciated because of its "millerays" look; the third method is anyway an empirical and inconstant means based on the fabric screwing and its subsequent cut, considering the fact that the fabric has already been screwed and therefore cut in a "twisted warp" way (what has already been crooked won't be crooked,in the same way what has fallen on the ground cannot fall any longer)

What mentioned above, however, cannot be done in a sure and constant way. The coming of the "open" machines, which cut the fabric during weaving in order to avoid forming any tubular crease, has not made possible the helical cut solution, though produced on these machines.RESULTS: 3C Company has obtained a cut directly realised during knitting production, with an open-wide fabric winding, with a geometrical raised crooked angle and mathematically controlled in order to supply customers with a fabric without creases (which doubles on helical cuts ) and screwing problems.

DEMONSTRATIVE PICTURES

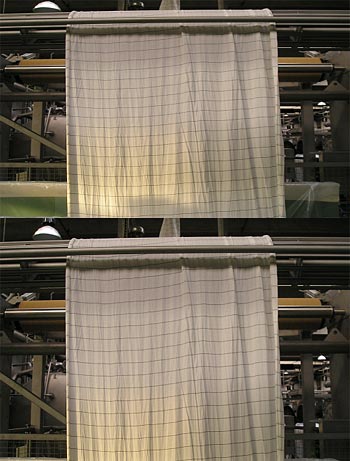

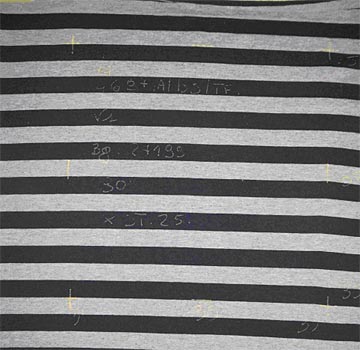

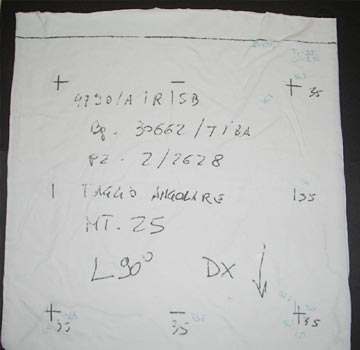

Taking as a reference a normal single jersey,we have added a horizontal line to show the horizontal course of the" right/twisted weft" and we have taken some needles off to show the course of the "right/twisted" warp.

Moreover we have woven some pieces with a "right warp" cut.

As You can see in the first pictures we have enclosed, please note how the "natural twisted weft" is shown: both before opening and after controlling.

As a result the weft looks twisted, but any "rameause" operation to straighten it would cause a fabric screwing. 2 enclosures

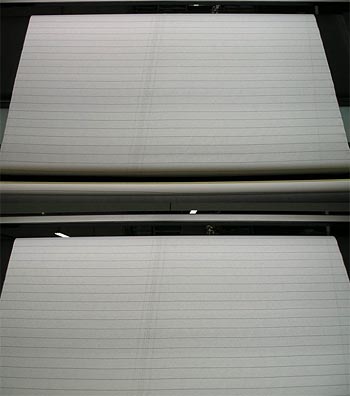

Subsequently we have woven other pieces of the same article and with the same line, but cut angularly during weaving with a pre-determined angle.

How You can see in the following pictures, fabric is shown both before opening and after a "right weft" finishing.

It will have a "twisted warp", but, after garment make-up and during following dyeings or washings, it won't screw significantly. 2 enclosures

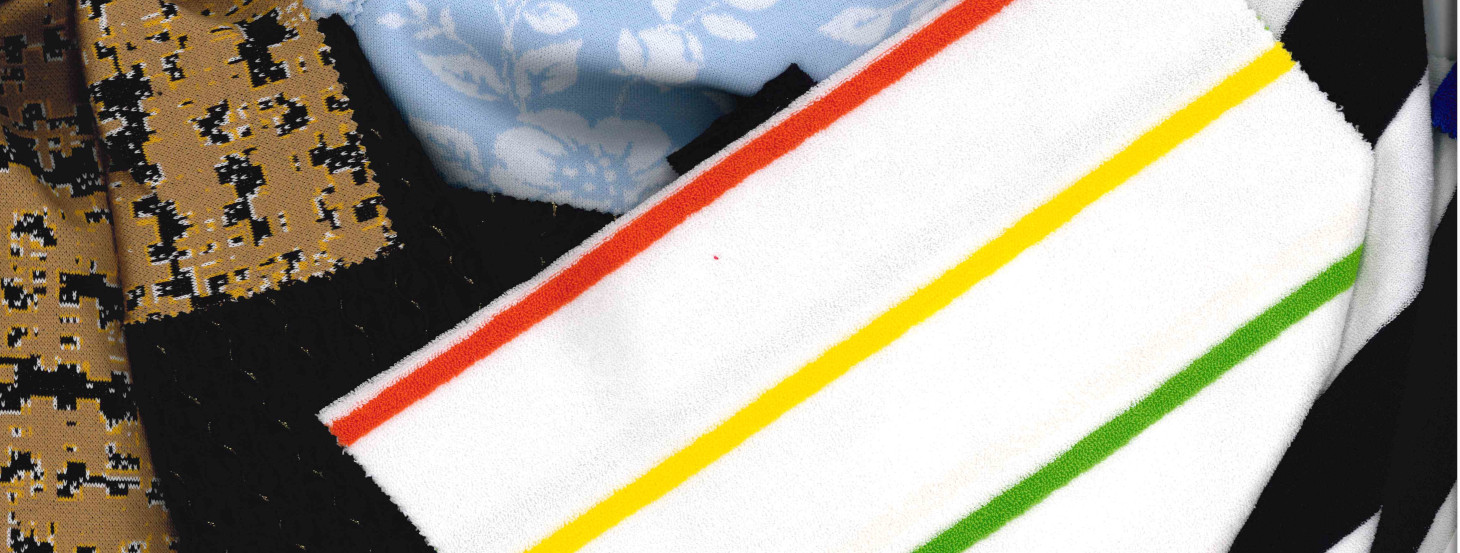

We can see stability tests on "no twist" fabrics where the square remains orthogonally correct.

And we can see tests on fabrics seamed like a sack, where seams don't move, as well as striped piece-dyed fabrics with the same results:

At the moment 3C Company is able to offer single jersey and derivatives,plain and striped fabrics,stretch or not,in fineness 24 and 28 with the use of cotton yarns from Ne 20/1 to Ne 40/1 having twists inferior to 20/25 grades.

We are doing experimentations and optimisations of technological performances in order to increase the range of finenesses to higher values (finenesses 32/38/40), with finer and consequently more twisted yarns (Ne 50/1,60/1,70/1,80/1,90/1 and so on).

In case of satisfying results the technique mentioned above can be developed also on new machines for different fabrics, both in single and double needle-bed. Please note: the technique used, even when perfect in production,cannot be miraculous.

You must consider, anyway, that knitted fabrics are subject to dyeing,finishing and check winding which could deform them; as a consequence we cannot answer for twisting values at absolute zero,but we can guarantee that with this technique garments will have always acceptable deformation indexes